- Type:

- Industry News

- Date

- 2026-Jan-27

How to choose the right size and type of Foldable Dog Cage for different dog breeds?

For B2B buyers, importers, and pet product developers, selecting the correct Foldable Dog Cage is a critical engineering and welfare decision that directly impacts canine safety, retailer satisfaction, and brand reputation. This technical guide provides a comprehensive, data-driven framework for matching cage specifications to breed-specific biomechanics, behavioral profiles, and commercial use cases, moving beyond generic advice to deliver actionable procurement criteria.

Fundamental Sizing Principles: An Ergonomic and Behavioral Approach

Correct sizing is a non-negotiable requirement rooted in animal ethology and kinesiology. A cage must allow for the full expression of species-specific postural adjustments—standing upright without head contact, turning around freely, and lying stretched out on the side. Scientifically, the internal length should equal the dog's body length (from nose tip to tail root) plus an additional 15-20 cm for comfort clearance. The internal height must exceed the dog's withers height (shoulder height) by at least 10-15 cm to permit normal head carriage.

Critically, exceeding these minimums excessively can be counterproductive, especially for training purposes. An overly large space can undermine the den-like security feeling, potentially hinder housetraining, and fail to provide the safe containment required during travel or recovery. For puppies, a common strategy is to purchase a cage matching the projected adult size and use a movable, secure partition to adjust the available space as the dog grows.

Breed-Specific Sizing Matrix and Commercial Classification

The most reliable sizing method combines weight guidelines with breed-specific morphology. The following table provides a commercial and welfare-aligned sizing framework, essential for buyers categorizing inventory or developing product lines.

| Cage Size (Commercial) | Target Weight Range | Key Breed Examples | Minimum Internal Dimensions (LxWxH) Recommendation | Primary Use Case |

| Small (S) | Up to 11 kg (25 lbs) | Shih Tzu, Pomeranian, Miniature Poodle | 70cm x 50cm x 55cm (28" x 20" x 22") | Home, vet visits, small car travel |

| Medium (M) | 11 - 25 kg (25 - 55 lbs) | Cocker Spaniel, Beagle, Border Collie | 90cm x 60cm x 70cm (36" x 24" x 28") | Home, training, standard vehicle travel |

| Large (L) | 25 - 40 kg (55 - 88 lbs) | Labrador Retriever, German Shepherd, Siberian Husky | 110cm x 70cm x 80cm (42" x 28" x 32") | Often considered the best foldable dog crate for large dogs for home and secure travel. |

| Extra-Large (XL) | 40+ kg (88+ lbs) | Great Dane, Mastiff, Saint Bernard | 130cm x 80cm x 90cm+ (51" x 32" x 36"+) | Requires reinforced structure; home and large vehicle use. |

Morphological Exceptions: Long-bodied, short-legged breeds (e.g., Dachshunds) require length over height. Tall, narrow-chested breeds (e.g., Greyhounds) require sufficient length for a fully reclined, outstretched posture that is critical for their skeletal comfort.

Material and Structural Analysis: Matching Type to Breed and Application

The choice between cage types is a function of material properties, mechanical design, and the dog's behavioral tendencies.

Comparative Analysis of Primary Cage Types

| Type & Material | Core Engineering Advantages | Limitations & Risk Factors | Ideal Breed & Application Match |

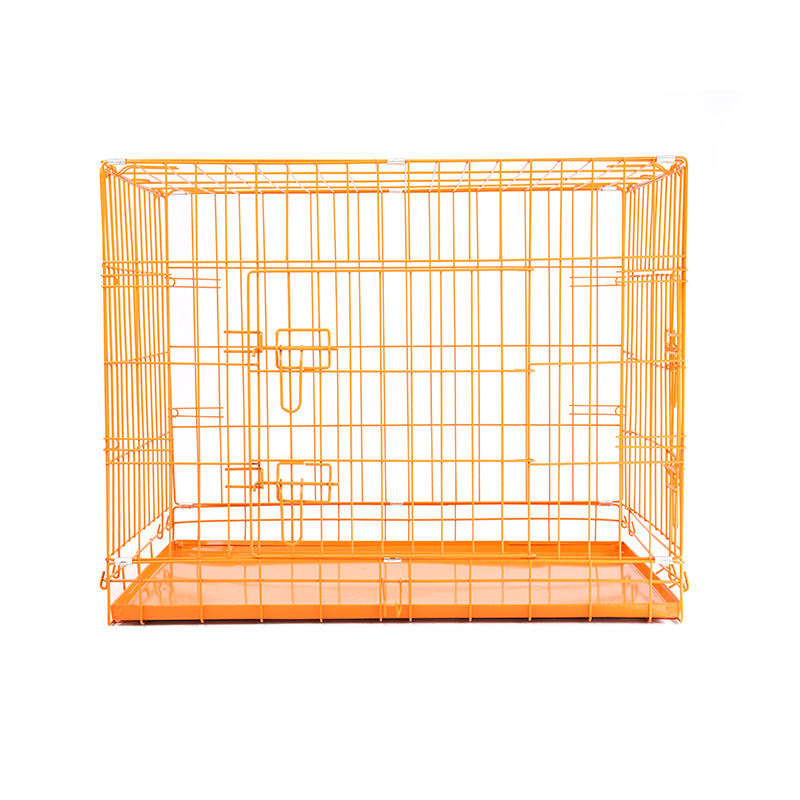

| Folding Wire Mesh | Maximized ventilation, superior visibility (reduces anxiety), high structural rigidity, long-term durability. | Heavier, less insulative, may require a foldable wire dog crate cover for privacy/draft control. | Most breeds for home use; high-energy dogs; brachycephalic breeds (for ventilation). |

| Soft-Sided (Fabric & Frame) | Lightweight, highly portable, compact storage, often includes padded floor. | Low resistance to chewing/digging, limited ventilation, less stable, difficult to sanitize. | Small, calm breeds; short-duration car travel; temporary indoor containment. |

| Folding Plastic (Airline Kennel) | IATA-compliant design, draft-resistant, easy-clean surfaces, provides den-like security. | Ventilation can be restrictive, heavier than soft-sided, bulkier when folded. | The standard for a foldable dog crate travel airline approved solution; anxious dogs; vehicle transport. |

The Case for Heavy-Duty Engineering

For powerful, determined, or anxious chewers (e.g., some terriers, working line shepherds, rescue dogs), standard cages pose a safety risk. A heavy duty foldable dog cage is defined by specific engineering enhancements: use of thicker-gauge steel (e.g., 4mm+ diameter wires), reinforced corner joints with double or welded locking mechanisms, and advanced, non-toxic powder coatings designed to resist jaw pressure and persistent scratching. These features are non-negotiable for shelter, boarding, and professional handling applications to ensure containment integrity and animal welfare.

Industry Standards, Safety, and Material Innovation

The pet containment industry is evolving beyond basic function. According to the latest market analysis by the American Pet Products Association (APPA), a significant and growing segment of professional buyers and informed consumers now prioritize products with verifiable safety certifications and sustainable material profiles. This shift is driving demand for cages that not only meet size and strength requirements but also feature components certified to non-toxic material standards (like FDA-compliant plastics and lead-free, chip-resistant coatings) and incorporate post-consumer recycled (PCR) metals where structurally feasible.

Source: American Pet Products Association (APPA) - 2024-2025 Pet Industry Market Size & Ownership Trends

This focus on verifiable quality and responsible manufacturing aligns with the core mission of established producers like Nantong Dihang Metal Products Co., Ltd. Since 2015, Dihang has specialized in the engineering and export of pet containment solutions. Their focus on innovative design and craftsmanship in Foldable Dog Cages and fences necessitates a deep understanding of these evolving material and safety standards. By controlling the manufacturing process—from material selection to welding and finishing—a company like Dihang can ensure each product batch meets precise specifications for gauge strength, joint integrity, and coating durability, which are critical for B2B partners sourcing reliable, brand-safe inventory.

Operational Protocols: Assembly, Inspection, and Maintenance

Proper deployment is as critical as selection. A standardized approach to how to assemble foldable dog crate units ensures safety and longevity.

- Pre-Assembly Inspection: Check all components against the packing list. Inspect for any shipping damage, sharp burrs on metal edges, or defective locking mechanisms.

- Structured Assembly Process:

- Lay the folded unit on a soft, non-slip surface.

- Simultaneously lift opposite sides of the base frame until it clicks into a rectangle.

- Raise the front, back, and side panels in sequence, ensuring each hinge or locking pin engages audibly.

- Attach the door panel, verifying the latch engages smoothly and securely on both sides.

- Post-Assembly Safety Check: Apply gentle but firm pressure to all sides to test for instability. Ensure the door cannot be pried open with moderate force. For wire models, confirm the provided foldable wire dog crate cover or tray fits securely without gaps.

- Maintenance Schedule: Recommend periodic checks for loose bolts, stress fractures at weld points, fabric tears, or coating degradation. Wire cages should be cleaned with pet-safe disinfectants and dried thoroughly to prevent rust.

Frequently Asked Questions (FAQ)

1. What are the absolute minimum dimensions for an airline-approved crate?

IATA Live Animals Regulations (LAR) mandate that the animal must be able to stand, turn, and lie down naturally. While each airline sets its own strict policy, the crate must typically be tall enough for the dog's ears not to touch the roof when standing, and long enough for it to lie down without curling excessively. The internal dimensions derived from the dog's measurements, as outlined in this guide, form the scientific basis for compliance. Always verify with the specific airline's cargo department for their exact crate size requirements before travel.

2. Can a heavy-duty wire crate be considered airline-approved?

Almost never. For air cargo, a foldable dog crate travel airline approved must be a rigid, ventilated plastic kennel with specific door bolt mechanisms, ventilation hole placement, and "Live Animal" labels. Wire crates are generally prohibited in cargo holds due to potential collapse risk if other cargo shifts. They may be allowed in the passenger cabin as carry-on if they fit under the seat, subject to airline size and material rules.

3. How do I select between a wire crate and a plastic kennel for a powerful chewer?

For a determined chewer, a standard wire crate is a significant hazard, as dogs can break teeth or bend wires. A heavy duty foldable dog cage with reinforced, thick-gauge steel is the appropriate wire-based choice. However, a structurally sound, reinforced plastic airline kennel can sometimes be more resistant to chewing on edges and corners. The ultimate solution often combines the right hardware with behavioral training and supervised use.

4. Is a soft-sided crate suitable for a puppy or an untrained dog?

No. Soft-sided crates are highly vulnerable to destruction by chewing, digging, or scratching. For puppies undergoing teething or untrained dogs who may experience confinement anxiety, a soft crate poses a ingestion risk (from swallowed fabric and foam) and a failure risk, leading to escape. A more secure wire or plastic crate is mandatory for safety during the training phase.

5. What is the most common error in crate assembly that compromises safety?

The most critical error is failing to ensure all locking pins, hinges, or latches are fully engaged before use. A partially assembled crate can collapse unexpectedly. Following a methodical process for how to assemble foldable dog crate units, including a final stress test by applying pressure to the panels and vigorously testing the door latch, is essential to prevent this failure mode.

Inquiry

Inquiry

English

English 中文简体

中文简体 Deutsch

Deutsch