- Type:

- Industry News

- Date

- 2026-Jan-01

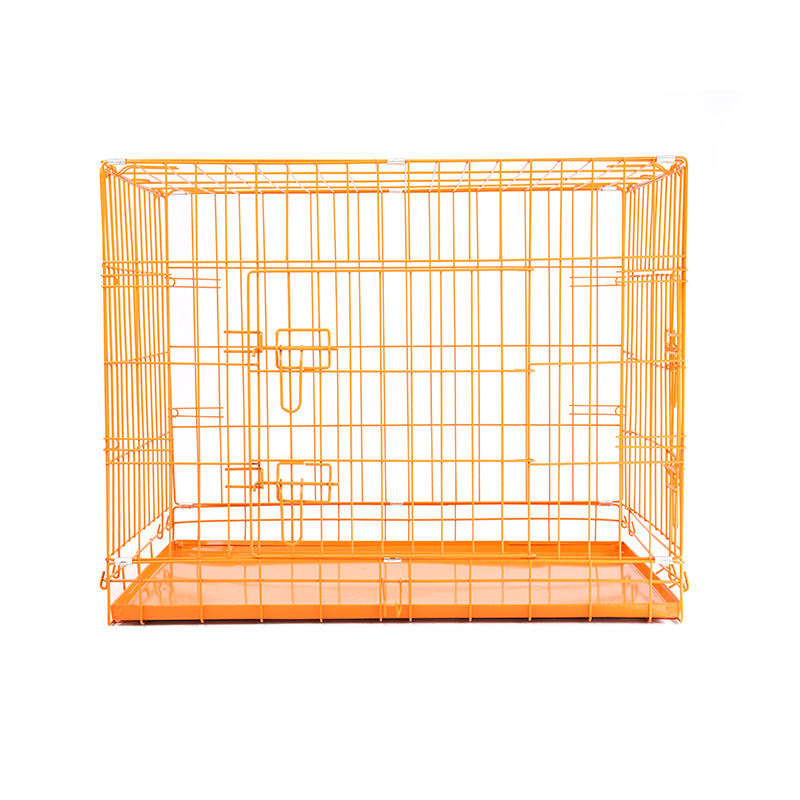

What are the Key Safety and Durability Features to Look for in a Foldable Dog Cage?

For pet professionals, breeders, and discerning owners, a foldable dog cage is more than a convenience item—it is a critical piece of equipment that must guarantee animal welfare and withstand rigorous use. The core challenge lies in balancing portability with uncompromising structural integrity. This engineering-focused analysis dissects the essential safety and durability features, moving beyond marketing claims to examine material science, design principles, and performance standards that define a truly reliable enclosure.

Material Science: The Foundation of Durability

Long-term durability is dictated by the materials and construction methods employed. The frame is the primary load-bearing component, and its specification is paramount.

Frame Analysis: The Case for Steel

A heavy duty foldable steel dog cage sets the benchmark for strength. The key metrics are steel type, thickness (gauge), and diameter. Low-carbon steel with a high-quality electroplated or powder-coated finish offers an optimal balance of strength, formability, and corrosion resistance. Tube diameter and wall thickness directly influence resistance to bending; for large or strong dogs, a minimum of 19mm diameter with a substantial wall is recommended. The powder-coating process, involving electrostatic application and thermal curing, provides a uniform, resilient barrier superior to standard paint in chip and scratch resistance.

Critical Junctures: Hinges, Latches, and Welds

The folding mechanism introduces inherent points of potential failure. High-quality cages feature:

- Reinforced Hinges: Fabricated from thicker gauge steel than the frame itself, often with a pinned or bolted construction rather than simple spot welding.

- Positive Locking Latches: Engineered with a secure, over-center action. Dual locking systems, combining a primary latch with a secondary safety bolt, are a hallmark of secure design.

- Clean Welds: Welds should be continuous, smooth (ground down), and free of splatter to prevent injury and indicate controlled manufacturing.

Core Safety Features: An Engineering Perspective

Safety is a multi-faceted requirement encompassing structural stability, internal safety, and environmental control.

Structural Stability and Containment

- Anti-Tip Design: A wide base footprint relative to height lowers the center of gravity. Some models integrate non-slip feet or base skirts to prevent lateral shifting.

- Mesh Geometry and Gauge: Wire spacing must prevent a dog from pushing its muzzle or paws through, a risk governed by breed and size. A thicker gauge wire (a lower number in the AWG standard) resists bending and chewing.

- Ventilation Standards: Adequate airflow is critical. A well-designed cage ensures ventilation openings are distributed across multiple sides, comprising at least 30% of the total wall area to prevent heat buildup.

Meeting Certification for Transit

For travel, an airline approved foldable dog crate must adhere to strict regulations. The International Air Transport Association (IATA) sets guidelines that often exceed typical "sturdy" consumer expectations. Key requirements include:

- Riveted or bolted construction (spot-welded mesh is often prohibited).

- Specific handle and locking mechanisms that cannot be operated by the animal.

- Rigorous strength and rigidity tests simulating cargo hold conditions.

Always verify the specific approval for the airline in question, as interpretations of IATA guidelines can vary.

Enhanced Features for Specific Use Cases

Specialized applications demand tailored engineering solutions beyond the basic cage structure.

Engineered for Large Breeds and Travel

A foldable dog cage for large breed travel necessitates specific reinforcements. This includes additional horizontal cross-bracing on the doors and side panels to counteract the substantial leverage a large dog can apply. The floor must be supported by a closely spaced grid of load-bearing beams to prevent sagging under significant weight over time.

Outdoor and Multi-Functional Designs

The requirements for a foldable dog playpen with carrying case and a waterproof foldable outdoor dog kennel converge on material resilience. For outdoor use, the focus shifts:

| Feature | Standard Indoor/Garden Cage | Heavy-Duty Outdoor/All-Weather Kennel |

| Weather Protection | Optional, often removable fabric cover. | Integrated, durable waterproof roof (e.g., coated Oxford fabric) and raised floor for drainage. |

| UV Resistance | Standard powder coat may suffice. | Enhanced UV-inhibited coatings and fabric treatments to prevent fading and polymer degradation. |

| Portability System | Simple handles or basic straps. | Padded, reinforced carrying case with robust zippers and shoulder straps for heavier folded units. |

| Base/Floor | Removable plastic tray. | Often a welded, coated wire grid to allow waste and moisture to pass through, promoting hygiene. |

Industry Standards, Testing, and Quality Verification

Procurement decisions should be informed by objective standards. While a universal industrial standard for pet cages is still evolving, responsible manufacturers subject products to tests simulating years of use.

According to a 2024 industry white paper from the Pet Industry Sustainability Coalition (PISC), there is a growing movement toward standardizing durability and safety tests for crates and carriers. This includes cyclic load testing on doors and latches, accelerated corrosion testing (like salt spray ASTM B117) for coatings, and chew-resistance simulations. Furthermore, the latest 2025 draft update to the ASTM F2057-23 (Standard Safety Specification for Clothing Storage Units) has spurred discussions about applying similar stability and tip-over test methodologies to large, freestanding pet enclosures, highlighting an increased regulatory focus on pet product safety.

Source: Pet Industry Sustainability Coalition - 2024 Materials & Safety Report

Source: ASTM International - Standard F2057

For immediate quality assessment, a buyer can perform a simple but effective checklist: apply firm lateral pressure to test for racking, vigorously shake the assembled cage to check for rattles or flex, open and close latches hundreds of times to feel for consistent action, and inspect all interior surfaces for smoothness.

Frequently Asked Questions (FAQ)

1. Is powder-coated steel always better than wire cages with an epoxy finish?

In terms of durability and safety, a high-quality powder coat is generally superior. The process creates a thicker, more uniform, and chemically bonded layer that is highly resistant to chipping, scratching, and corrosion compared to most liquid-applied epoxy paints. This makes it the preferred finish for a heavy duty foldable steel dog cage intended for long-term or outdoor use.

2. How do I accurately calculate the correct size cage for my growing puppy or specific breed?

Use breed-specific adult dimensions as your guide. The cage must allow the dog to stand without its head touching the top, turn around freely, and lie down stretched out. For a foldable dog cage for large breed travel, add an additional margin for comfort during long journeys. Never size a cage based on a puppy's current size alone; project for its expected adult size to avoid costly replacements.

3. Can a foldable cage be made truly "escape-proof" for a determined or anxious dog?

No cage is 100% escape-proof, but security can be maximized. Focus on features like double-latching doors, latches positioned externally or with protective covers, and reinforced door frames. For persistent escape artists, especially with a foldable dog playpen with carrying case style (which often has more panel connections), supplement with secondary security clips or carabiners at every panel junction.

4. What are the realistic maintenance requirements to ensure long-term durability?

Regular maintenance is crucial. Wipe down the frame with a damp cloth; avoid abrasive cleaners that can damage the coating. For a waterproof foldable outdoor dog kennel, regularly clear debris from the roof and check drainage. Inspect all latches, hinges, and welds monthly for signs of wear, rust, or stress. Lubricate moving parts with a silicone-based lubricant (not oil, which attracts dirt) to ensure smooth operation.

5. Are soft-sided or mesh panels in a folding playpen as safe and durable as all-steel designs?

They serve different purposes. Soft-sided panels offer lightweight portability and are excellent for supervised, contained play in a foldable dog playpen with carrying case. However, they are not suitable for containment of chewers, diggers, or anxious dogs, and they lack the structural security and long-term durability of a welded steel cage. For primary confinement, unsupervised use, or travel, an all-steel or heavy-duty hybrid design is the only appropriate choice from a safety and durability standpoint.

Inquiry

Inquiry

English

English 中文简体

中文简体 Deutsch

Deutsch